The profession of the future

Aiforsite’s Productivity Engineer Lari Perttula explains: “On paper, I am an external consultant, but in practice, I work so closely with site management that I am part of a site organisation. The productivity engineer in the construction industry is the profession of the future, so I feel like I am doing pioneering work. I help the parties of the construction project track what they do together analytically by making productivity pitfalls visible. This gives time to address the shortcomings.”

Today, tight construction project schedules and busy construction sites are commonplace. Contractors operate on low margins, and productivity in the industry is low. From project to project, contractors struggle with the same challenges: staying on schedule, keeping costs under control, and doing work to the agreed quality level.

The primary task of the productivity engineer is to help the site stay on schedule. This is not about one contractor but the whole site. Everyone needs to be doing their own thing at the right time. This improves productivity.

What does the productivity engineer do?

Improving productivity in the manufacturing industry by streamlining production processes and eliminating waste has long been commonplace. In the construction sector, the situation is different, although, for example, lean thinking and takt production are becoming more common.

“As a productivity engineer, I am part of a transformation that aims to apply the best lessons of the manufacturing industry to the construction industry.

My work combines the roles of a detective, an analyst, and a consultant. In practice, I follow the progress of the project compared to the schedule. When I notice deviations, I look for the reasons behind them. In addition, I am proposing solutions to eliminate the waste caused by deviations. I also present the proposed solutions to the contractors and monitor their implementation, so my job is more than just influencing the background and waving the consultant’s hands.”

What tools does the productivity engineer use?

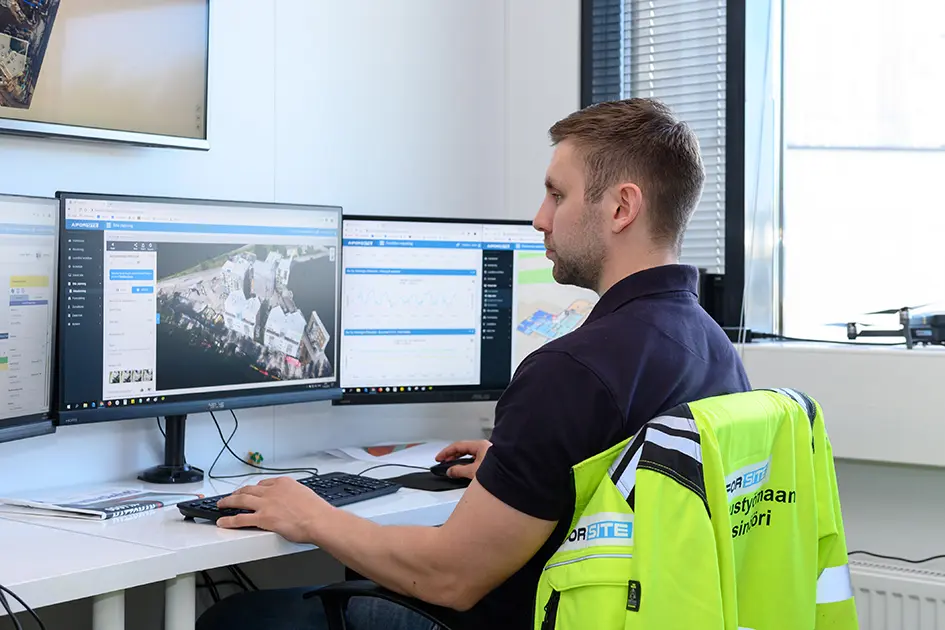

”I monitor the construction project’s progress remotely using site cameras, 360 ° camera shots performed at an agreed frequency, and a positioning information system. These are all part of Aiforsite’s solution. In addition, I have access to the main contractor’s scheduling and logistics systems as well as a project bank with the latest plans.”

”The positioning system is essential for eliminating waste. I use it to monitor whether human resources have been where they should be. If the resources have been elsewhere than where they should be or the job area has been left frequently, I use cameras to determine the cause.”

How does the positioning system work?

“Positioning data is needed to monitor the progress of the entire construction site and different work areas. The main goal of the whole job is to ensure that the work in the different work areas is completed according to the planned schedule.”

”At the beginning of the cooperation, we provide the contractors with “tags”, i.e. tracking devices that transmit their location information to the system. Typically, workers attach tags to their helmets with a sticker or cable tie.”

”The word ”tracking tag” sounds scary, so I want to emphasise that they are not used to monitor individuals. That would not even be possible, as no personal data is recorded on the tags, and we do not register the bearers of the tags. Tags are tracked based on a serial number that is appended to a professional title (e.g., carpenter) in our system to track the progress of the task.”

How does the productivity engineer contribute to eliminating waste in practice?

”The easiest way to explain is through an example: at a construction site, we found from the positioning system that plumbers were constantly visiting the basement, causing interruptions to work. We saw from the cameras that they had a storage and machining point in the basement, where they cut the pipes to a suitable length.

All the extra work and moving of the materials around the site is a waste. So, we suggested moving the machining point closer or pre-order the pipes in the correct dimensions. These measures increased continuous work and reduced the extra movement of materials.”

Who does the productivity engineer report?

”I report to the site management. I actively participate in the site meetings. I attend the weekly meeting of the main contractor and the weekly subcontractor meeting, where the management of the subcontractors is also present.

At the weekly meeting with the main contractor, we will review the findings and deviations related to the previous week’s productivity. In addition, I present proposals for measures to improve productivity.

At the subcontractor’s meeting, we will discuss the findings with the contractors’ management and share development suggestions to make the work more efficient.”

Who is the best person for the job?

”The most important criterion for a productivity engineer is the desire to be part of the development of the construction industry. In practice, success in work requires the foreman or civil engineer’s education and sufficient work experience so that, for example, reading schedules and identifying deviations do not present challenges.

Depending on the background, I would say that a skilled person will learn to do the work of a productivity engineer independently in about a few months,” sums up Lari Perttula.