- AIFORSITE AIC

Win on productivity

Choose the fast and practical way to stay competitive and build better.

Platform introduction

Winner's choice

Aiforsite is a fast and most practical way to succeed and the only solution that focuses on improving productivity of the direct work.

The key winning factor is ensuring the right task prerequisites and maximising the share of direct work (tool-time).

The Aiforsite Platform offers real-time task-specific measurement of the tool-time productivity.

The AI-driven technology helps identify the root causes of wasted time and plan actions to improve tasks’ prerequisites.

Methodology, service, and AI-powered technology

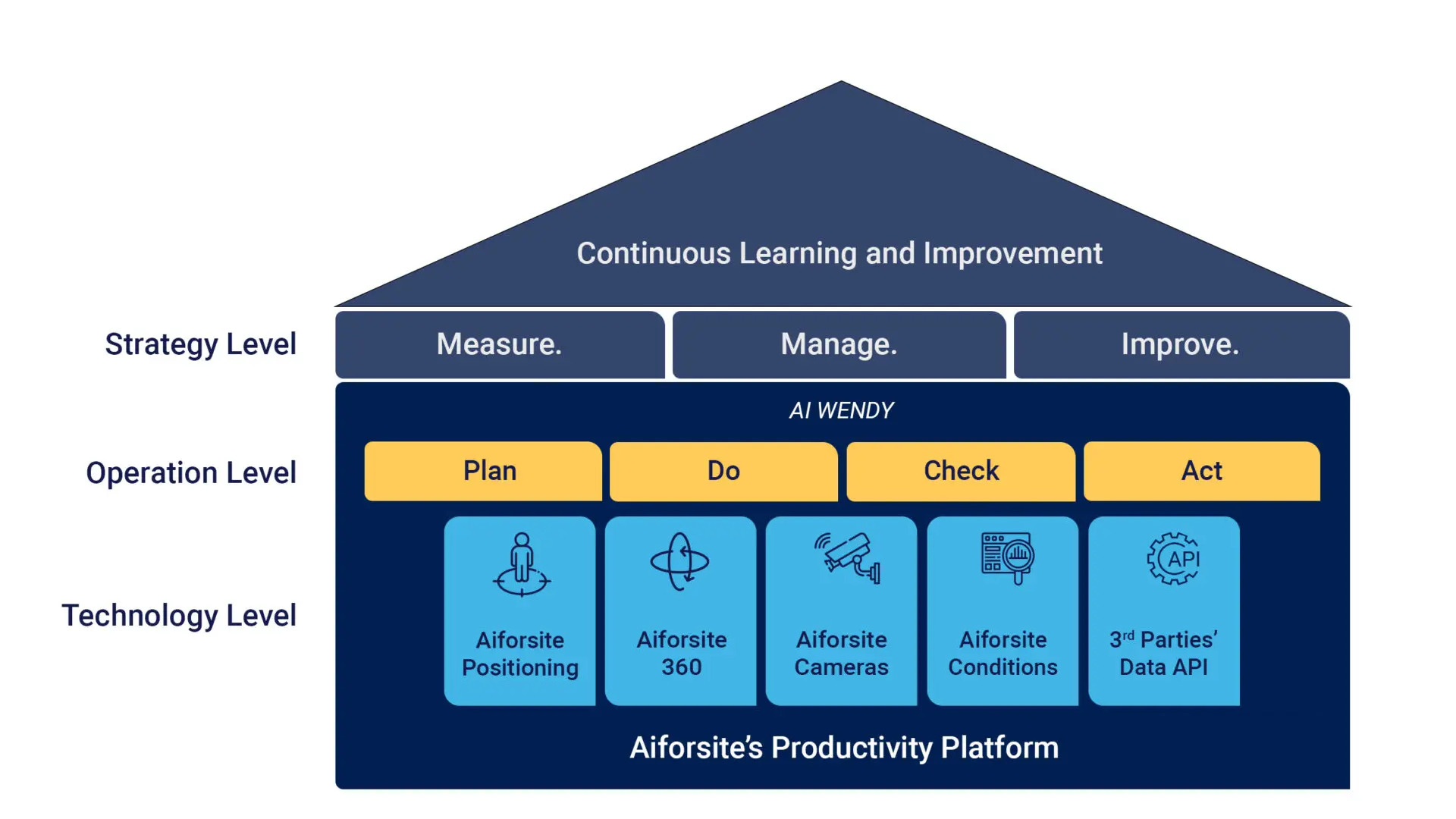

Aiforsite’s method is rooted in lean principles of continuous learning and improvement.

1 of 5The three-phase framework for strategic thinkers: measure your current productivity level, manage by data, and expand continuous improvement to the whole project portfolio.

2 of 5AI Wendy is a virtual assistant of the construction site management that helps running the site and managing contractors.

3 of 5Continuous improvement process follows lean PDCA cycle on weekly basis. Aiforsite’s Productivity Engineer supports and trains the site team to adopt new working methods.

4 of 5One platform provides you with all necessary site data to reinforce your real-time situational awareness.

5 of 5How does the Aiforsite model work?

By using technology, data and Productivity Engineer services, contractors lead the change and manage construction site productivity continuously.

Site productivity management

Plan next production phase

Technology

Productivity Report

Tasks of Productivity Engineer

Create Productivity Report

Data utilised

Productive work time

Actual schedule status

Logistics KPIs

Condition Analysis

Site productivity management

Compare reality against plans

Technology

Productivity Analytics

Tasks of Productivity Engineer

Identify schedule deviations

Perform root cause &

productivity analysis

Data utilised

Presence and productive work time

Production area monitoring

Contractor monitoring

Logistics (customer data)

Site productivity management

Check task prerequisites

Technology

Site Visualisation Conditions Management

Tasks of Productivity Engineer

Identify deviations and analyse task prerequisites

Data utilised

Site Cameras

360 Video

Drone Model

Conditions data

Logistics (customer data)

Continuous Improvement

Smart Products

Multiple data sources create a big picture

Aiforsite productivity management platform utilises multiple data sources, which are grouped into five Smart Products -modules. Each of the modules has its particular function, and many of them are used in construction as a single-point solutions.

In our platform, they have one common role – to create a real-time big picture of the progress and help you work without hassle.

By using Aiforsite, you will benefit from the individual features of different tools in one interface, but the main benefit is the ability to track, measure, and improve your real productivity on the construction site.

Smart Products -modules

Real-Time Location System

Real-Time Location System is a core function of the productivity management platform. It provides you with real-time information about how productive the work is. The main goal is to ensure that the work in the different work areas is completed according to the planned schedule.

Real-Time Location System is the main source of real-time data for tracking and measuring the share of productive installation work. The positioning data is also a matter of occupational safety in case of emergency situations at the site.

Real-time situational awareness

Real-time situational awareness is one of three cornerstones of Aiforsite Real-Time Location System. The system tracks contractors by their professional functions, for example, “carpenters” or “electricians”. Other modules of the Aiforsite platform, like 360 videos or site cameras, complement the big real-time picture.

Productivity Engineer Service

The Productivity Engineer service is particularly useful for those contractors who are just starting their productivity journey. The Productivity Engineer is your guide and an extra resource in your site management team. Read more about how the Productivity Engineer can help you.

Real-time productivity analytics

The system compares planned work schedules for programmes and tasks to real-time data. You will see at a glance where the installers spent their time, how much of this time was productive, what tasks were completed as planned and where you have problems.

360 Reality Capture

360 images and videos are essential for visual checking of task prerequisites at workspaces. It is also a great help to have evidence of how the work has been done and to settle possible disputes with project stakeholders during the construction period, as well as the guarantee and maintenance period.

You not only document the site progress in 360 photos and videos but manage and improve the productivity of work.

Aiforsite 360 Reality Capture enables site inspections and reporting the deviations without going to the site. The project stakeholders stay informed and can manage mandatory site visits remotely.

Site Cameras

Site cameras are the source of a real-time view of the site and working areas. The Aiforsite Site Cameras module offers external and interior site cameras for real-time situational awareness. Site cameras are used for

- Remote monitoring work during the day – not always necessary to go to the site

- the safety of workers during material lifting

- Having real-time visual access to the site for the client and other stakeholders

- Complementing surveillance cameras on the site

- Preventing thefts

Condition Monitoring

Condition monitoring and management are crucial for ensuring the required prerequisites for the tasks. Aiforsite’s automatic wireless technology brings effective tools for managing the conditions of construction sites and ensuring that the schedule is kept. You can quickly monitor the site conditions in real-time and react if the set alarm limits are activated. All measurement data and reports are stored in the cloud system.

We utilise wireless sensor technology for monitoring cast-in-situ concrete strength and dryness, air temperature and humidity, as well as pollution.

DataHUB

A home for all data

The DataHUB is an integral part of the platform and is included in each module. The DataHUB stores all the data collected from the site by using Aiforsite’s technology.

The DataHUB can be connected to your project file share, or it can act as one if you prefer. The benefit of such is that the collected data and your project planning and other documents are stored in the same location.